Advantages:

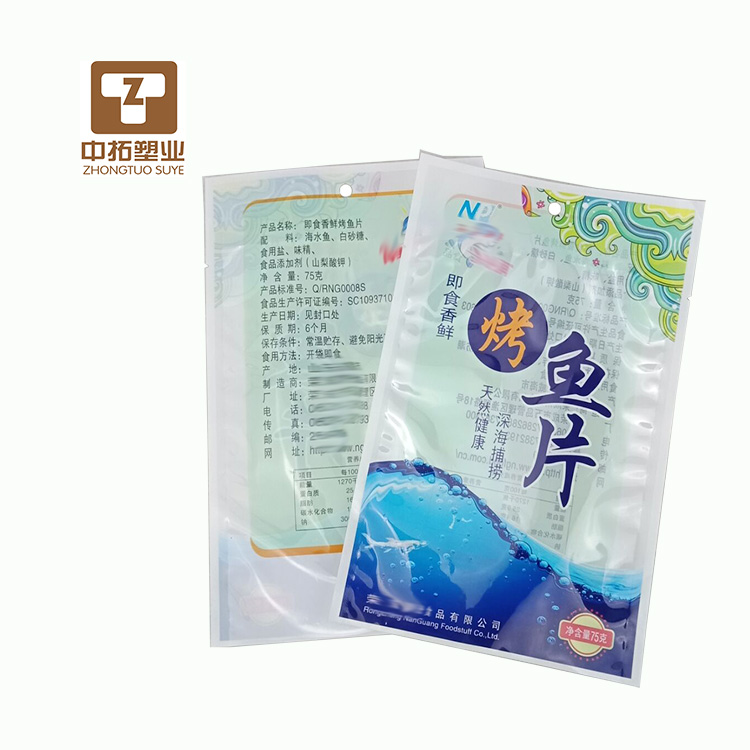

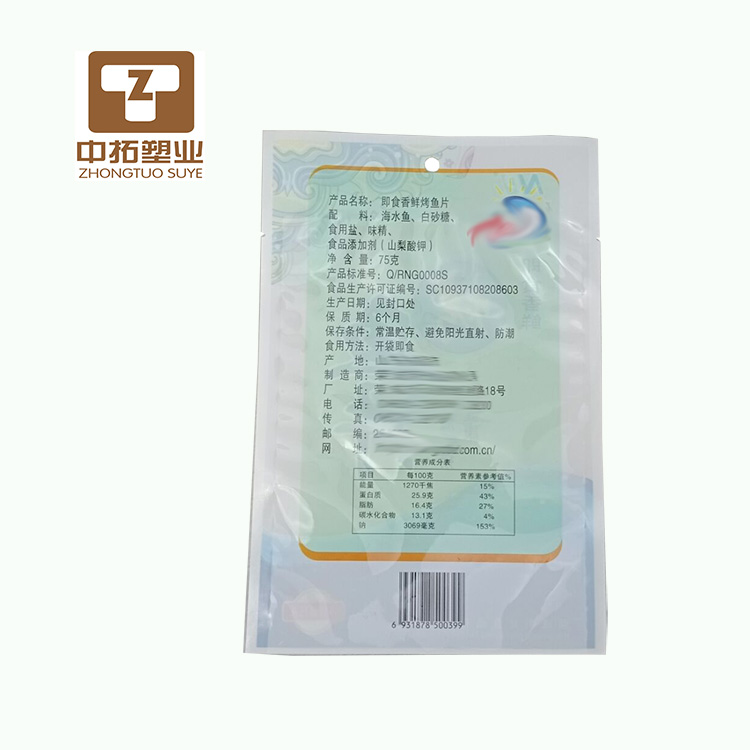

1. Advanced professional equipment to ensure good quality assurance, safety, non-toxicity, good sealing

2. Strong toughness and firmness, professional testing can detect the corresponding toughness and firmness.

3. Custom printing: can be printed according to customer requirements, exquisite packaging image, can quickly attract the attention of consumers, is conducive to improving product image and competitiveness

4. Professional manufacturer, with more than ten years of production experience and stable customer base

5. All pet food bags are made of food-grade materials, environmentally friendly and non-toxic, with CQC certification.

6. Qingdao Entry-Exit Inspection and Quarantine Bureau approved "self-service inspection and quarantine reporting unit" (registration number: S370209)

7. QS Production License Certification Number LuXK16-204-00982 and ISO 9001, ISO14001 Certification

8. Advanced laboratory and laboratory equipment to provide you with perfect solutions

9. Perfect after-sales service, so that you have no worries

Cooperation process:

1. Consulting/Selecting Products

2. Determining Cooperation Intention

3. Making and providing samples free of charge

4. Customer Confirmation of Our Samples

5. Contractual payment

6. Production of finished products by sample

7. Customer Acceptance

8. Quality after-sales service

Production process:

1. Office Center, pre-design, typesetting, scheduling, ordering of packaging products, etc.

2. Dust-free printing workshop of production department: YAH-8100 high-speed gravure printing machine, 1050mm electronic axis high-speed printing machine, high performance, fast and stable printing for you, using environmentally friendly non-toxic benzene-free ink.

3. Dust-free compound workshop of production department: FHJ-1200 high-speed fully automatic dry compound machine, which can compound the printed single-layer materials into the number of layers you need, and the compounded materials are rolled into the ripening room. The glue used for compounding is edible glue.

4. Dust-free slitting workshop of production department: KWF-T automatic high-speed slitting machine cuts the redundant parts of printed, composite and ripened material rolls into the range you need, with the error less than 0.8mm.

5. Dust-free bag-making workshop of production department: 13 fully automatic high-speed bag-making machines are controlled by computer. They are controlled by PLC, fixed length by double servo motors and real-time display by LCD touch screen. They are completed at one time from feeding, sealing, cutting, punching and conveying, with high automation and good economic benefits.

6. Dustless Inspection Workshop of Quality Department: Under the perfect inspection management system of our company, several employees operate several precision inspection equipments to provide you with reassurance for your packaging products.